- cross-posted to:

- [email protected]

- cross-posted to:

- [email protected]

There’s all kinds of info in here about freeze dryers that I never knew I didn’t know.

I still don’t want a freeze dryer, but I can now speak authoritatively as to why.

Not sure I can commit to an hour of this but I’m curious why shouldn’t someone, per the video?

Primarily because it’s a $3k piece of equipment. There are myriad other food preservation methods (canning, pickling, drying etc) that compete very strongly on the price/performance scale.

For some people it’s worth it, but for most use cases it’s going to be cheaper and simpler to go with an alternative method. There’s nothing wrong with the equipment or the technique, it’s just the value proposition for the consumer is low and the entry cost is high.

- They’re REALLY expensive $3k for his unit which isn’t even the top end.

- They’re loud

- They run for an entire day for one batch

- They consume a massive amount of electricity (1 day freeze dryer vs 30 days of a regular freezer)

- The prep time for the food its VERY extensive.

- If you don’t prep just right the food is wasted

- the amount of actual food produced is really small

- Even if you’re fine with everything else, shockingly few things actually taste good after freeze drying.

Additionally:

- while the food will taste the same, in most cases the mouth feel is so horrendously bad it will be inedible

- rehydration of most foods is very hard to impossible, limiting it’s uses even more

- if you put more than one kind of food in a batch, the chance of error in the process increase dramatically, because all food needs different amounts of time to dry

I’m pretty sure the only actual use cases are berries and fruits. But those can all just be dehydrated normally or made into jam, so there is little to no purpose for a freeze dryer, except playing around with foods, which is not worth the price

I’m pretty sure the only actual use cases are berries and fruits.

Also great for making great hash out of weed

I still think his point could have been made twice as convincingly through the magic of buying two of them

He bought two sets of trays. Close enough

Lol. In this case you don’t really need to take it apart since the guts of it are exposed on the bottom . Otherwise I think he would have.

No one in my family gets why I say that, but whenever I buy two one something, I use that line lol makes me smile

I could see maybe renting one as part of renting a professional kitchen setup where some of the prep is easier and they should have large freezers to make that part take less time. But owning one? No, absolutely not.

So, in theory if you had a vacuum pump and put the vacuum chamber in a freezer, would that just be a much slower freeze dryer?

So, in theory if you had a vacuum pump and put the vacuum chamber in a freezer, would that just be a much slower freeze dryer?

The description you have is nearly identical to the freeze dryer reviewed. The one feature missing from what you’re describing and the commercial product reviewed was the commercial product had warmers for the trays to speed up sublimation. Besides the tray warmers, the freeze dryer was a vacuum chamber wrapped in a freezer.

That’s my thinking, but he never went it into. I was really hoping he would

This video is very long and entertaining and there’s a lot of evidence of the effort he put into it. The one real criticism I have is that it seems like he didn’t do a lot of research on what foods work well with freeze drying, preferring to do his own experiments and getting gnarly results on basically everything that isn’t already a well-known freeze dried product.

Personally I think one of the most useful things to freeze dry would be fresh, home grown herbs. Another big one is homemade soups and stocks.

As for the usefulness of freeze dried food? The big one he missed is camping and hiking. Frozen foods just aren’t going to cut it when you’re away from electricity for a week or more. You need lightweight non perishable food and for that nothing beats freeze dried. Just need to get some water from a lake or river!

I still want one. I’m never, ever going to buy one, even if I could afford it. But I love freeze dried snacks, and I also love food preservation, and don’t mind tedious prep. It’s right up my alley. But they’re too expensive, and use too much energy. I’d feel guilty as fuck from an environmental standpoint.

Watching TC do a video about something I do professionally has been a bit of a trip. For context, I work with freeze dryers (we call them lyophilizers) in pharmaceuticals rather than foods. I help design the lyophilization cycles for biologics and gene therapy products that get preserved through freeze drying. Until this video, I had no idea that people used these instruments for at-home food preservation (which is kind of insane imo).

The instruments that I work with are typically a much larger version of the bench-scale machine that he is using (usually one of the LyoStar line). However, I have used smaller, bench-scale units as well for some quick and dirty work. I included some pictures at the end behind a spoiler tag. Happy to answer any questions people have.

Some differences in how I use lyophilizers in a scientific setting as opposed to a home-use food setting:

- Typically, we only lyo products that are already filled in vials as opposed to a full tray like he’s done.

- We don’t pre-freeze our products before they go into the lyophilizer. Instead we refrigerate the shelf that the vials are sitting on to freeze the contents before we proceed to the drying steps.

- Speaking of the shelves, in our instrument, the shelves can move up and down. This is used to compress the vials after the cycle is completely done, fully seating the vial stoppers and sealing them before we open up the main door.

- Also speaking about stoppering the vials, we typically allow some nitrogen into the chamber before sealing up the vials, at a pressure moderately less than atmospheric pressure. This helps keep the vial sealed until it is properly crimped with a seal.

- When it comes to drying, we do it in two stages. The primary drying step is when our product is kept cold, but put under vacuum. This removes most of the water, but not enough for our purposes. The secondary drying step is when the product is heated while the vacuum is maintained. This removes the rest of the water. We typically shoot for a residual moisture of <1% for a good cycle.

- He talks about how long the process takes. I have worked on processes that take from 1-5 days. Typically, the lyophilizer is limited with how much liquid can be removed per unit time. This limit is determined by the geometry of the vent that connects the main chamber with your vials, and the chamber containing the condenser. Also, if you try to dry too quickly, it can damage the product you are trying to preserve.

- He has some discussion at the end about the end of the cycle and the progress bar. What the instrument is doing is comparing the vapor pressure in the chamber using two different sensors. One of those is sensitive to the vapor pressure of water vapor, and the other is not. So, when things are fully dried out, those two are going to read the same pressure. While drying is still occurring, the sensor that detects water vapor will read a higher pressure. So, the instrument will continue to extend drying until those two pressures are the same.

Some Pictures

Benchtop lyophilizer that I have experience using. You can see some vials lined up inside the door. I have never used the bottle connections hanging off the side:

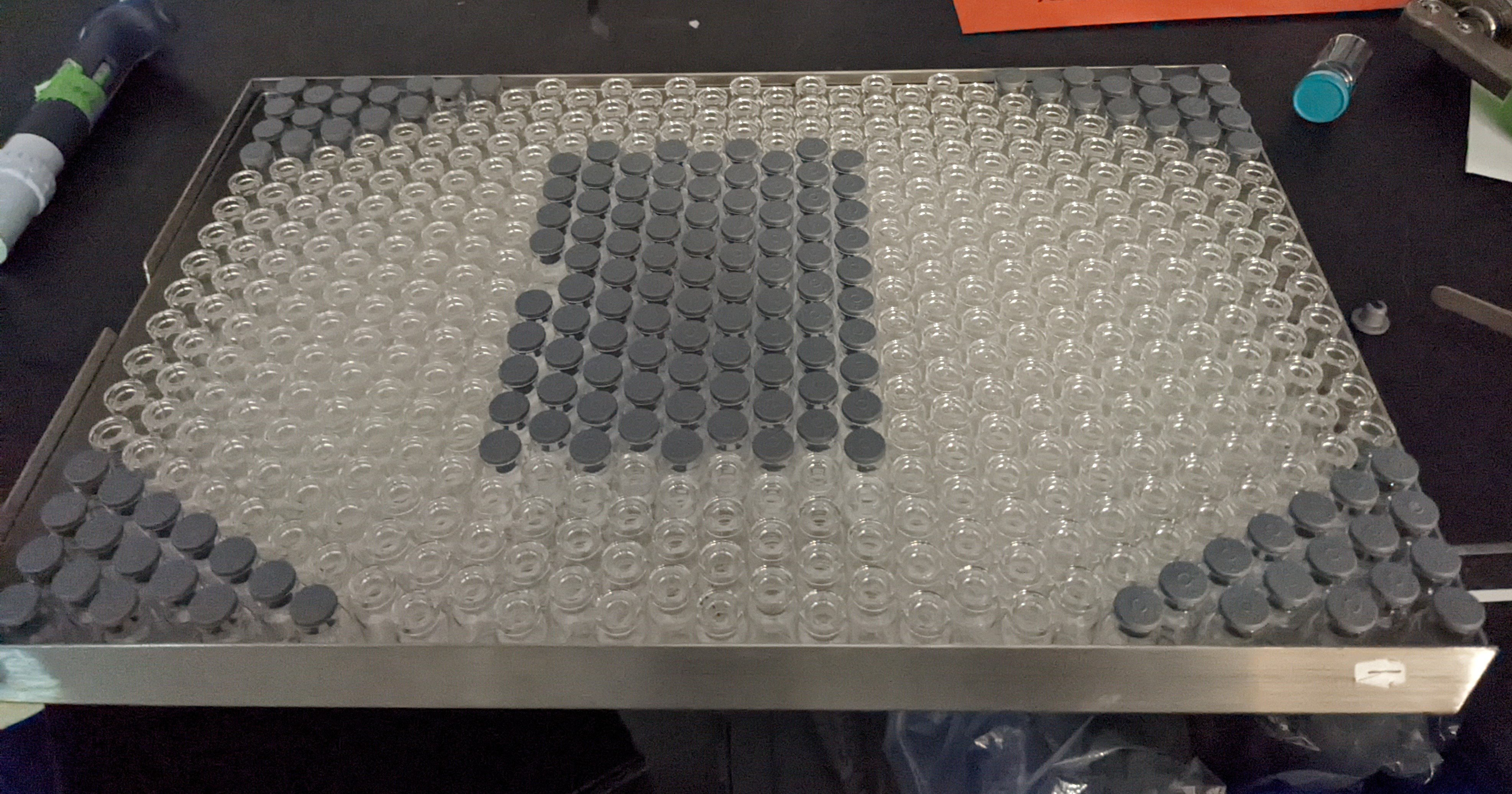

One of the trays of vials that is loaded before going into the lyophilizer. The vials that are partially stoppered in the middle of the tray actually contain the drug. All the vials without stoppers are empty and simply there to help hold things in place as well as distribute heat predictably through the tray. The stoppered vials in the corners are there to help distribute the weight as the shelves compress to fully seat the stoppers.

Here are a small number of vials that I ran on a benchtop unit without any spacer vials or the tray. I would never do this for any reason other than to take a picture like this. This is a good view of what a partially stoppered vial looks like. It allows a path for water vapor to escape out the top of the vial.

Finally, here is a vial post-lyophilization. The liquid has turned into a solid, white cake at the bottom of the vial. This is because most lyophilization formulations include sugars that provide structure for the cake and keep it porous. The sugars provide protection against freeze/thaw stress for the molecule of interest as well. The porosity of the cake allows for quick and easy reconstitution by adding water, usually in <30 seconds or so.

I’ve reconstituted a ton of lyophilized vials of controls for medical lab analyzers. Interesting to hear about how they’re made, thanks for sharing.

What an interesting read. You made my day!

What are thaw things you process used for?

The products I work on are mostly monoclonal antibodies (and the occasional gene therapy product mixed in). So, the types of diseases they are used to treat vary. To be honest, I work on the process/formulation side of the development pipleline and the actual clinical treatment part is pretty much inconsequential to what I do. Some of the past programs I have worked on include treatments for asthma, eczema, multiple myeloma, breast cancer, MS, hemophilia, and tons of others that I don’t remember. Often, when dealing with antibodies, the same medicine can be effective for multiple indications.

The finished vials, post-lyophilization, sealing, labeling, and packaging, are sent to infusion clinics. There, clinicians will add water to the vials to reconstitute the drugs and then administer them to patients via IV (usually).