deleted by creator

- 147 Posts

- 1.68K Comments

2·1 day ago

2·1 day agoI think I did at one point but it did not work for me. That was a long time ago though.

5·1 day ago

5·1 day agoThe kernel started moving faster, but also the kernel for these devices are orphans. They can never be updated properly because the source code for the kernel modules is not available. The way the phones get updated in ROMs is by back porting changes from the present back to the old orphan. It requires someone super familiar with both kernels to do so. Eventually it becomes untenable. The whole scheme of Android is centered around this source code/orphan kernel scheme. Everything is setup so that hardware manufacturers never have to add their source to the mainline kernel meaning you can never own the device. There is not a single phone or mobile device that you can completely own and running on mainline with available source code. The pixel is all about the TPM chip.

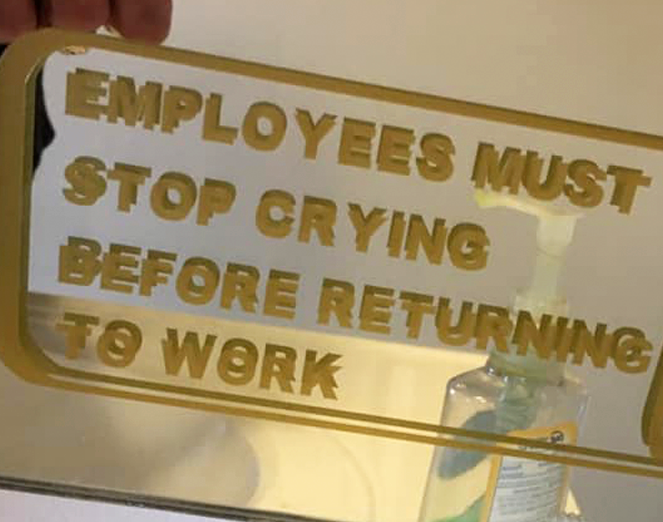

Unfunny double layer joke on joke but your meme is pretty

13·2 days ago

13·2 days agoWhy did my health insurance cost double with no explanation…

2·2 days ago

2·2 days agoShebangs

big tate hate failed French & fried rule

11·2 days ago

11·2 days agoHumans are subsentient animals unfit to self govern. We are only sentient cosplay. The drones scare me most. That will be AI controlled soon. Every other application of AI does not scare me in the present, but this one, small cheap drones are terrifying unlike any other weapons.

584·2 days ago

584·2 days agoNot a single sauce opened, no bites taken, nothing removed from an annoying tray lip and placed on the table like a real person. No sign whatsoever that they are actually eating this junk. The half eaten fries are staged as eating without the ketchup that is right there on the tray is quite unlikely.

This is a staged ad. It is meant to be a message to others in corporate America, and for marketing to convenient idiots to quote the Russian term.

5·2 days ago

5·2 days agoPixel 4 is past EOL with Graphene (and google)

1·2 days ago

1·2 days agoSamy usually requires Odin3 to flash ROMs – which requires a m$ 4 pane trash shoot OS. I haven’t used m$ since the Samy S3 Galaxy era, so things may have changed but I doubt it.

572·2 days ago

572·2 days agoI am surprised it took you this long.

The next step in this evolutionary thinking is simple. Buying hardware specs is a fool’s folly. I don’t compare hardware. Ads and marketing are totally nonsense and not worth even a slight glance. The ONLY thing that matters is what open source projects exist and what hardware do they support well. This is how I shop. Open Source or F.O.

1313·3 days ago

1313·3 days agoMy life is on a trajectory to homelessness with disability and a system that refuses to help me. This is me, in the future, being traumatized, abused, and dying in a gutter somewhere while being criminalized because a political refugee from the other side of the world had to have a driver’s license but had the cognitive capacity of a third grader. I was just commuting to work on a bicycle, a racer, upper middle class guy, working in a chain of high end bike shops. I’m you on an extremely unlucky day. You’re only one bad day away from this exact same issue.

2155·3 days ago

2155·3 days agoEmpty words from scum Newsom, the tormentor of the homeless and needy.

11·3 days ago

11·3 days agoDon’t know much about Stein, but most of what I’ve heard from Sanders sounds like the kind of sanity that the asylum riots to resist. The USA has no Left.

4·3 days ago

4·3 days ago(👉👈)

5·3 days ago

5·3 days agoI’m around 50:50, I read a lot of them but am prone to cynical hot takes on occasion. I’m particularly interested in social community and feeling like I’m at least present with others. Physical disability and in my case, the social isolation it causes–sucks. I’m here when I’m not able to do much else and need to escape. So that is my excuse for the times I’m not reading and the overly cynical hot takes.

That explains it. I made it through the entire Eaternet, the bread board computer, 6502; all that. But pipelines and out of order instructions of the girl-matrix are just beyond my registers.

51·3 days ago

51·3 days agopolitically correct in a more social the kind of thing a person should do context, like cultural norms

Corporate media