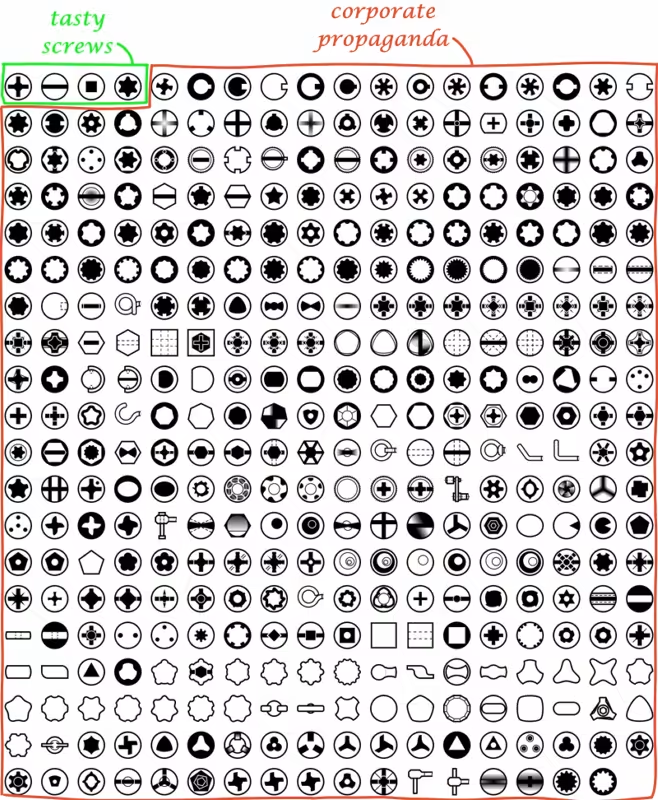

I kinda miss a few opinions on the topic of “screw taste” here. 🥲

old version:

The only reason robertson isn’t the standard in NA is because the inventor was a moron and wouldn’t license the production to ford

TBF Henry Ford was a literal Nazi and I probably wouldn’t want to license anything to him either.

Pozi and Torx are my jam. They all taste the same though. Yup, I keep 3 or 4 on the side of the mouth when I’m working on a ladder. Nothing beats nails if you want taste.

Ehh the s type screw is pretty nostalgic for me. It takes me back to the days in school drawing that cool S all over my notebook and then eating the page.

Whoever designed the Phillips/Square combo screw shall burn in the seventh circle of hell. That thing is a disaster.

Correction: they’re a disaster if you use them with a Philips driver. Try a Robertson next time.

I hate it because it strips, if you look at it funny… any other reasons I should hate it?

Kinda surprised this wasn’t a gender comic. I half expected the corpo propaganda label to be mental illness lol

And torx is the tastiest screw, fight me

I love torx, but posidrive, triangle, and even spanner all hold a special place.

I won’t fight you brother, I will join you, torx is the best screw, doesn’t strip, Philips is literally built to slip under pressure

spanner is pretty tasty usually for me but phillips and slotted depends on where it was. id argue thats propaganda since its seen everywhere. specialized screws i think are usually upkept well enough to be tasty.

I prefer torx to Philips. Philips strips too easily

Reject screw. Return to nail.

Half of these look like anime eyes.

I don’t like philips. They wear out fast and leave behind a rounded cavity that makes the screw useless.

The only screws Phillips makes are when screwing their customers over.

Slotted screws belong in the trailerpark

If a screw is totally stripped it’s nice to use a Dremel to just cut a slot and then be able to extract the screw.

The argument being: if it wasn’t a slotted screw before, it is now?

The thing with slotted screws is that the screw itself is awful, but a flathead screwdriver in and of itself is such a useful tool you’re always gonna have one, so the screw kinda hangs around.

No mention of Oval drive? As much as I normally hate security fasteners, I love those for being hilarious. At first glance it appears roughly circular, you’d be like “well this is a nail, or a rivet or something”. But no, actually you can unscrew it!

Yeah, but unfortunately it has to protrude from the surface because the bit grabs the outside, which means you can also grab it with pliers. Not the best feature for a “security” fastener.

Omg you’re right!! I didn’t think about that at all… It’d be difficult but certainly doable.

You could reverse it so the socket is on the screw instead, but then it might be slightly more obvious that it is a screw. Also nobody makes those, to my knowledge.

I have never seen this. I love it! It’s so simple! Why are these not everywhere?!

Right?! And yet AFAIK there is exactly one (now defunct) company who ever used them. I guess it’s time to be the change we want to see in the world 😈

Phillips exists to auto center and prevent over tightening. This auto centers but doesn’t prevent overtighteninf so you can theoretically torque the head right off. Otherwise it’s great.

and prevent over tightening

That’s a funny way of saying “it’s designed to strip out and become unusable as easily as possible”, but to each their own.

Oh it absolutly does that, which is why I hate it, but it was intended to so exactly that for a different reason.

Both Phillips and slot screws are fucking awful.

Yeah flat heads are terrible. They are always the reason if I get injured by my screwdriver.

Firstly, theres no geometry preventing the bit from slipping out. Secondly, greatly exacerbating the first, you need to press hard to prevent the bit from camming out, which increases the risk of it slipping out.

Both problems combined causes the bit to slip out with very high force. If you happen to be holding the workpiece, you can injure yourself real bad.

I fucking hate flatheads.

Flat heads exist because they were the only thing we could make for a long time.

Philips was made to strip heads.

Hexagon the the true master head. No camming out and If it starts to strip, you can smack it with hammer to return it to a working shape.

IMO the only two criteria that matter are:

- Is the screw going to slip out while I’m screwing it in or out.

- Do I have a screwdriver or screwdriver tip for that screw when I need it.

Criterion 1 eliminates the flat head and Philips points. They’re terrible because they slip out. The flat head not only slips out, it slips out in the most dangerous ways.

But, criterion 2 eliminates most of the other designs. Even if you’re Canadian, which means you do have a Robertson screw driver, you might not have the right Robertson bit. Unlike with Philips or slot, the size of the bit really matters.

Ikea does a great job of handling this situation because they mostly use hex screws and bolts (which are great), but they also supply the required driver with the parts (which is necessary because many people don’t have a tool to tighten hex bolts).

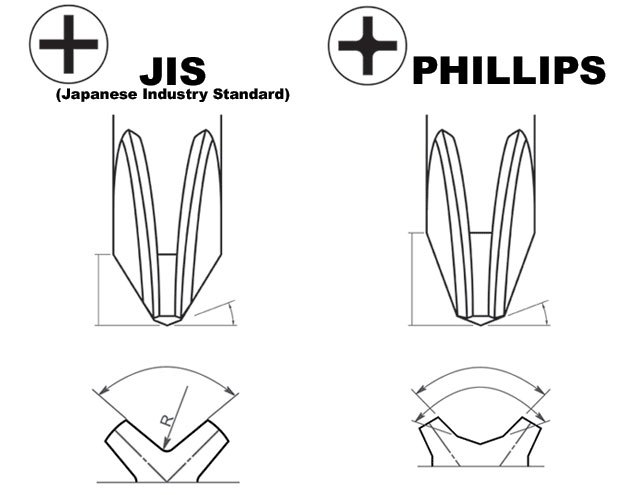

JIS > Philips and this is a hill I will die on. Philips #2 strips so quickly its quickly garbage.

This article I came across convincingly disputes the idea that JIS is meaningfully different from other cross head standards. I do not have access to the standards myself to corroborate.

What’s jis look like

Oh interesting

Treat yourself to some good drivers from Vessel and you are living the high life. Or don’t and strip every screw you look at on old Japanese motorcycles.

Philips apparently got adopted because it strips so easily. Back in the day, torque limiters didn’t work well and camming out was considered preferable to applying too much torque

That’s the point of Philips. They’re for assembly line manufacturing designed to torque out when they’re tight.They’re awful.The problem with JIS is that most people don’t have a JIS driver.

Wikipedia disputes the claim of cam out being deliberate

The design is often criticized for its tendency to cam out at lower torque levels than other “cross head” designs. There has long been a popular belief that this was a deliberate feature of the design, to assemble aluminium aircraft without overtightening the fasteners.[15]: 85 [16] There is no good evidence for this suggestion, and the property is not mentioned in the original patents.[17]

Fair enough.

That makes them trash to me, if that’s not a feature.

Robertson and hex are fine. In the far reaches of the world those can be quite common.

Half of those screws are Robertson if you’re in a pinch.